As many industries are looking to minimize waste and save resources, the demand for recycled materials in the fashion industry has increased. However, recycling certain materials can sometimes be a tricky process, especially leather waste can be difficult to recycle. Much of the recycled leather contains harmful chemical residues, such as chromium VI, which result from the tanning process. These chemical residuals are carried through in the conventional recycling process.

To enable a planet positive industry, by accelerating vital research and supporting breakthrough innovation to scale, H&M Foundation is collaborating with HKRITA in the programme Planet First. One of the research projects, reProLeather, has resulted in a new technology to separate the chromium VI from the shredded leather fibres and create a bio-based, alternative to the PU and PVC binders, thereby creating a new form of recycled leather that is biodegradable and recyclable.

The reProLeather successfully restructured post-consumer leather fibres into leather sheets in its research stage. HKRITA is now seeking industry partners to optimize production properties and enhance functions, paving the way for improved industry applicability in the future.

“As a philanthropic change agent for the entire industry, we take risks to unlock needed solutions with the ambition to find technologies that can contribute to a planet positive fashion future. I’m always open to sharing our findings openly with others, to find industry actors ready to adopt bold innovations and reProLeather could be one of these solutions. I hope to see it scale soon.”

Christiane Dolva, Strategy Lead at H&M Foundation

The technology

reProLeather is a recycled leather system that separates, categorises and recycles post-consumer leather products into useful raw materials for the manufacturing of new products.

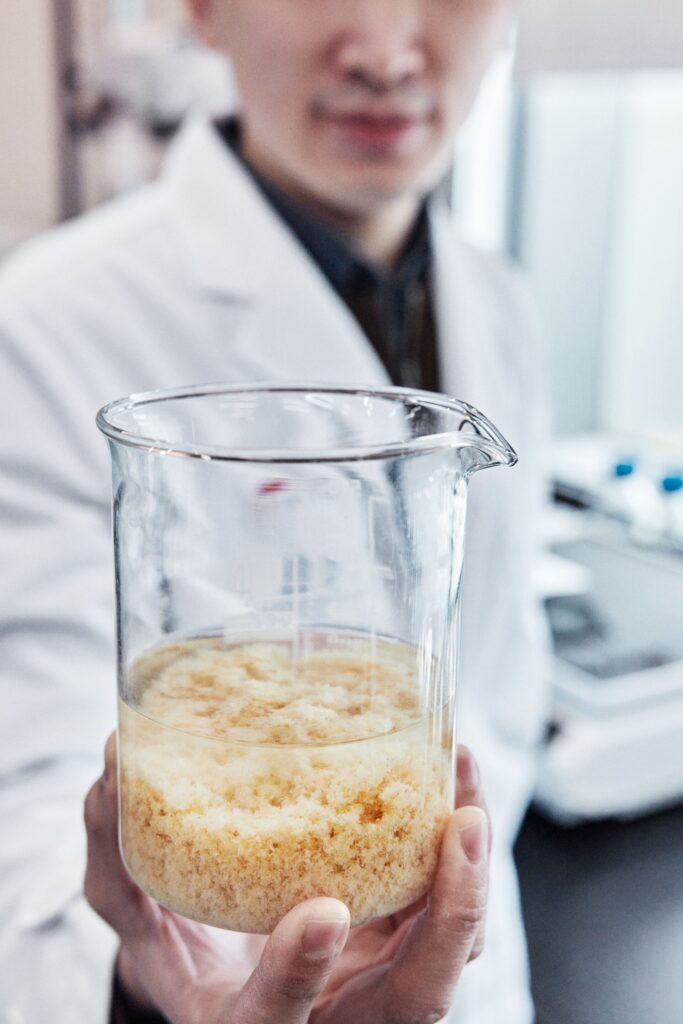

It is carried out in two steps, beginning with shredding a whole post-consumer leather product into pieces until leather fibres of high purity are obtained and removing free chromium by transforming it into a soluble salt or complex compound. Then the separated leather fibres react with bio-based binders such as sugar or protein under mild conditions, and collagen fibres become interconnected and form a new leather.

Regenerated leather obtained with such a novel bio-based approach is water-resistant and biodegradable, resulting in a ‘virtuous circle’ for leather recycling.

Key technological advancements:

- Utilizing environmentally friendly bio-based binders (e.g., sugar or protein) as substitutes for synthetic PU and PVC, resulting in a new sheet of leather.

- Employing a reaction process that minimizes the formation of toxic chromium VI during recycling.

- Successfully restructuring the pro-consumer leather fibres to form a leather sheet.

Benefits for the industry:

- Mitigating environmental harm and health concerns stemming from chrome tanning in leather production.

- Providing an eco-friendly alternative to traditional recycled leather.

- Incorporating raw collagen fibres that enhances the tactile experience.

- Ensuring the recycled leather is durable enough for further manufacturing.